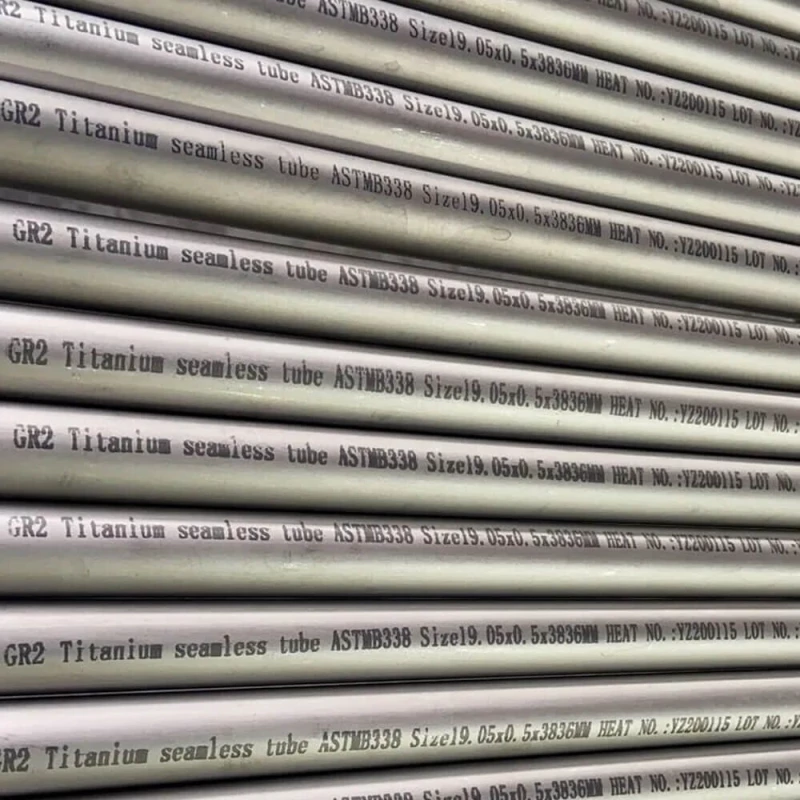

| Product Name | Pure Titanium & Titanium Alloy Tube /Pipe/Tubing/Titanium Hollow Bar/Capillary Titanium Tube | |||

| Titanium Grade | Gr1, Gr2, Gr5, Gr7, Gr9, Gr11, Gr12, Gr5Eli, Gr23 etc | |||

| Standard Comply | ASTM B338/ASME SB338, ASTM B337/ASME SB337, ASTM B861/ASME SB861, ASTM B862/ASME SB862,AMS4911,AMS4928 etc | |||

| Dimension Range | Outer Diameter: 3-114mm or as customized | |||

| Wall Thickness:0.2-50mm or as customized | ||||

| Tube Shape | Round, Square, Flat, Coil etc | |||

| Type | Seamless, Welded | |||

| Surface | Pickling, Polished, Bright finish etc. | |||

| End | Plain End, Beveled End, Threaded | |||

| Certificate | EN 10204/3.1B,/Raw Materials Certificate/100% Radiography Test Report/Third Party Inspection Report, etc | |||

| Test | Chemical composition, Mechanical Property, Eddy current testing, Ultrasonic testing,Hydraulic test etc | |||

| Application | Off-Shore Oil Drilling Companies/Power Generation/Petrochemicals/Gas Processing/Specialty Chemicals/Pharmaceuticals/Pharmaceutical | |||

| Equipment/Chemical Equipment/Sea Water Equipment/Heat Exchangers/Condensers/Pulp and Paper Industry | ||||

| Product Name | Cp1 Cp2 seamless titanium tube titanium pipe price per kg |

| Material | Pure titanium and Titanium alloy |

| Titanium Grade | Grade 1—Unalloyed titanium |

| Grade 2—Unalloyed titanium | |

| Grade 3—Unalloyed titanium | |

| Grade 7—Unalloyed titanium plus 0.12 to 0.25 %palladium | |

| Grade 9—Titanium alloy (3 % aluminum, 2.5 % vanadium) | |

| Grade 12—Titanium alloy (0.3 % molybdenum, 0.8 % nickel), | |

| Standard | ASTM B338/ASME SB338, ASTM B337/ASME SB337, ASTM B861/ASME SB861, ASTM B862/ASME SB862,AMS4911,AMS4928 |

| Shape | Round Square Rectangle |

| Type | Seamless/Welded |

| Processing | Seamless titanium tube: Titanium sponge—Compacting electrodes—melting—Forge—Bar billets—Extruding—Rolled—Straightening—Seamless tube |

| Welded titanium tube: Titanium sponge—Compacting electrodes—melting—Forge—Plate billets—Hot rolled—Cold rolled—Titanium scrap—Welded—Welded tube | |

| Surface | Polishing, picking, acid washed, black oxide |

| Application | 1) General service industries (petroleum, food, chemical, paper, fertilizer, fabric, aviation and nuclear |

| 2) Fluid, gas and oil transport | |

| 3) Pressure and heat transmission | |

| 4) Construction and ornament | |

| 5) Boiler heat exchangers | |

| 6) Motorbycle and bike | |

| Material Milling Certificate | According to. EN 10204.3.1 |

| Including Chemical composition and Mechanical property |

Titanium tubing are delivered in straight lengths or as U-bent tubing. Titanium spiral tubing, titanium capillary tubing are available by requirement. All the Titanium Tubing offered by us will pass strict test process.

Features:

Low density, High specific strength, Excellent corrosive resistance, No Rust, Good thermal stability, Good thermal conductivity, Biological features, Plasticity, etc.

Applications:

Industry field, aerospace, architectural, automotive, biomedical, chemical processing, marine, military, oil, tooling, racing.

Heat exchangers and condensers

All kinds of corrosive fluid transmission pipeline system

Titanium bicycle tube, automobile exhaust pipe

Offshore aquaculture

Inspection & Testing:

Ultrasonic testing, Electric non-destructive testing, Flaring testing, Hydrostatic testing, Flattening testing, Visual surface inspection, Dimensional inspection, Tensile properties inspection and Chemical elements analysis.

Advantage:

First-class product, Reasonable price, The fastest delivery.

100% Ultrasonic Test (UT), 100% Eddy Current Test(ET), 100% Pneumatic Test. 100% Hydraulic Test.

Technology Data Sheet

Grade

N

C

H

Fe

O

Al

V

Pd

Mo

Ni

Ti

Grade1

0.03

0.08

0.015

0.2

0.18

/

/

/

/

/

bal

Grade2

0.03

0.08

0.015

0.3

0.25

/

/

/

/

/

bal

Grade3

0.05

0.08

0.015

0.3

0.35

/

/

/

/

/

bal

Grade4

0.05

0.08

0.015

0.5

0.4

/

/

/

/

/

bal

Grade5

0.05

0.08

0.015

0.4

0.2

5.5~6.75

3.5~4.5

/

/

/

bal

Grade7

0.03

0.08

0.015

0.3

0.25

/

/

0.12~0.25

/

/

bal

Grade9

0.03

0.08

0.015

0.25

0.15

2.5~3.5

2.0~3.0

/

/

/

bal

Grade12

0.03

0.08

0.015

0.3

0.25

/

/

/

0.2~0.4

0.6~0.9

bal

Titanium Tubing Grades Guide:

Grade

Tensile strength(min)

Yield Strength(min)

Elongation(%)

ksi

MPa

ksi

MPa

Grade1

35

240

20

138

24

Grade2

50

345

40

275

20

Grade3

65

450

55

380

18

Grade4

80

550

70

483

15

Grade5

130

895

120

828

10

CP Grade 1 is the softest titanium with the highest ductility, good cold form-ability which gives Titanium Grade 1 an excellent resistance from mild to high oxidation. Commercially Pure Titanium Grade 1 is one of the softest and most ductile grades exhibiting the greatest formability. It also has excellent welding properties and high impact toughness. Titanium Grade 1 is designated as UNS R50250.

CP grade 2 is used most widely in the commercially pure titanium. Titanium Grade 2 has moderate strength and excellent cold forming properties.Titanium Grade 2 is designated as UNS R50400. Grade 2 Titanium is called the “workhorse” of the commercially pure titanium industry, thanks to its varied usability and wide availability. It is "unalloyed" titanium offering an excellent balance of strength and ductility.

CP grade 3 is almost only used in pressure vessel. Grade 3 titanium has excellent corrosion resistance.

Alloy Grade 5, Ti-6Al-4V, is most widely used in the titanium alloys because of its comprehensive mechanical, physical and chemical properties. Titanium 6Al-4V, Titanium Grade 5 alloy (UNS R56400) is the most widely used titanium grade. Titanium Grade 5 is a two phase α+β titanium alloy, with aluminum as the alpha stabilizer and vanadium as the beta stabilizer. Grade 5 titanium has good welding and fabrication characteristics.

Alloy Grade 23, Ti-6Al-4V ELI (Extra Low Interstitial) is designated as UNS R56401, Titanium Grade 23 has a superior damage tolerance to other alloys. These benefits make Titanium Grade 23 the ultimate dental and medical titanium grade.

Titanium 8Al-1Mo-1V is a near Alpha Alloy that was primarily designed for use at elevated temperatures - up to 455 degrees centigrade. It offers the highest modulus and lowest density of all Titanium alloys. It has good creep strength and it’s weldable by the inert gas fusion and resistance-welding processes.

Feature

1. Low Density and High Strength

2. Excellent Corrosion Resistance

3. Good resistance to effect of heat

4. Excellent Bearing to cryogenic property

5. Nonmagnetic and Non-toxic

6. Good thermal properties

7. Low Modulus of Elasticity

Temos mais categorias para você. Se você não pode encontrar os produtos que você quer acima, basta preencher o formulário e nos dizer quais produtos você quer importar da China.