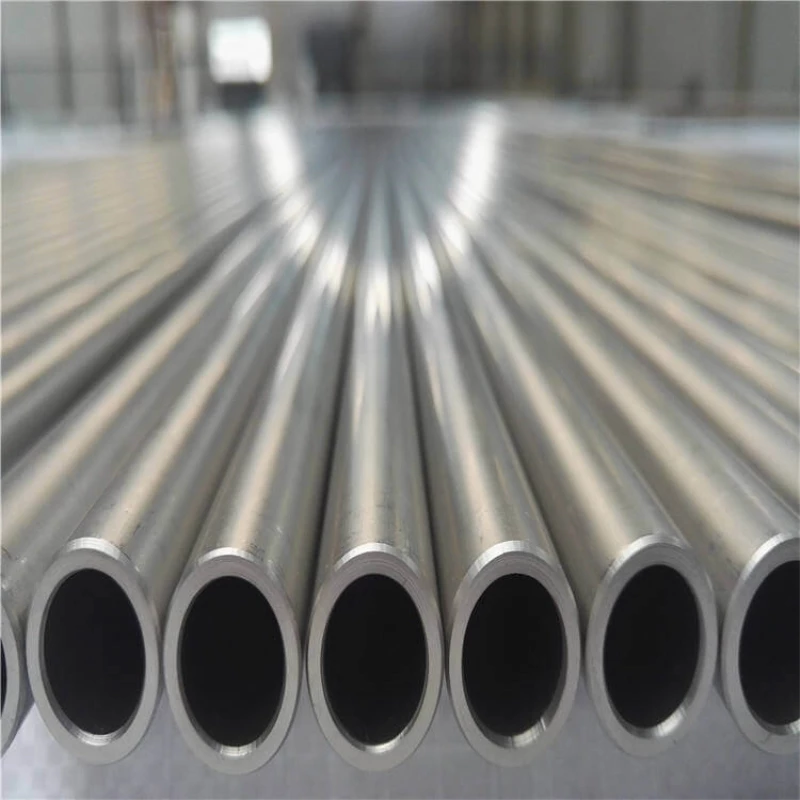

Titanium Tubes / Titanium Pipes.

The density of titanium is 4.506-4.516g/cm^3, melting point is 1668, boiling point is 3535. Therefore Titanium have low weight, excellent high strength and nonmagnetic festures, low density, excellent corrosion resistance features, high specificate strength and high temperature resistance features, so it is widely used in chemical industry field, medical field, electronics manufacture, mechanical parts field, automobile industry, and aerospace field, etc.

Production status of titanium alloy tube:

Hot working condition (R)

Cold working condition (Y)

Annealing state (M)

Titanium alloy tube manufacturing process:

Hot forging

Hot rolled

Annealing

Cold rolled

Pickling

Applications of titanium tube/pipe:

Industrial pure titanium pipe is not only very important and used in the aerospace and aviation industry, but also has been widely used in many industrial departments such as chemical industry, oil, light industry and power generation.

| Product Name | seamless titanium tube |

| Material | Pure titanium and Titanium alloy |

| Titanium Grade | Grade 1—Unalloyed titanium |

| Grade 2—Unalloyed titanium | |

| Grade 3—Unalloyed titanium | |

| Grade 7—Unalloyed titanium plus 0.12 to 0.25 %palladium | |

| Grade 9—Titanium alloy (3 % aluminum, 2.5 % vanadium) | |

| Grade 12—Titanium alloy (0.3 % molybdenum, 0.8 % nickel), | |

| Standard | ASTM B338/ASME SB338, ASTM B337/ASME SB337, ASTM B861/ASME SB861, ASTM B862/ASME SB862,AMS4911,AMS4928 |

| Shape | Round Square Rectangle |

| Type | Seamless/Welded |

| Processing | Seamless titanium tube: Titanium sponge—Compacting electrodes—melting—Forge—Bar billets—Extruding—Rolled—Straightening—Seamless tube Welded titanium tube: Titanium sponge—Compacting electrodes—melting—Forge—Plate billets—Hot rolled—Cold rolled—Titanium scrap—Welded—Welded tube |

| Surface | Polishing, picking, acid washed, black oxide |

| Application | 1) General service industries (petroleum, food, chemical, paper, fertilizer, fabric, aviation and nuclear |

| 2) Fluid, gas and oil transport | |

| 3) Pressure and heat transmission | |

| 4) Construction and ornament | |

| 5) Boiler heat exchangers | |

| 6) Motorbycle and bike | |

| Material Milling Certificate | According to. EN 10204.3.1 Including Chemical composition and Mechanical property |

Grade

ELEMENT COMPOSITION.%

Ti

Al

V

Fe

C

N

H

O

Other

Grade1

Blance

_

_

0.2

0.08

0.03

0.015

0.18

0.4

Grade2

Blance

_

_

0.3

0.08

0.03

0.015

0.25

0.4

Grade3

Blance

_

_

0.3

0.08

0.05

0.015

0.35

0.4

Grade5

Blance

5.5~6.75

3.5~4.5

0.4

0.08

0.05

0.015

0.2

0.4

Grade7

Blance

Pd(0.12~0.25)

_

0.3

0.08

0.03

0.015

0.25

0.4

Grade9

Blance

2.5~3.5

2.0~3.0

0.25

0.08

0.03

0.015

0.25

0.4

Grade38

Blance

Al(3.5~4.5)

V(2.0~3.0)

1.2~1.8

0.08

0.03

0.015

0.2~0.3

0.4

Material Reference

ISO

Composition

France

Russian

DIN

JIS

UNS

Standard

Standard

Standard

Standard

Standard

Standard

Grade1

CP1

T35

BT1-00

3.7025

TP270

UNS R50250

Grade2

CP2

T40

BT1-0

3.7035

TP340

UNS R50400

Grade7

Ti 0.2Pd

BT5-1

3.7255

TP340Pb

UNS R52400

Grade12

Ti 0.3Mo-0.8Ni

BT9

UNS R53400

Temos mais categorias para você. Se você não pode encontrar os produtos que você quer acima, basta preencher o formulário e nos dizer quais produtos você quer importar da China.